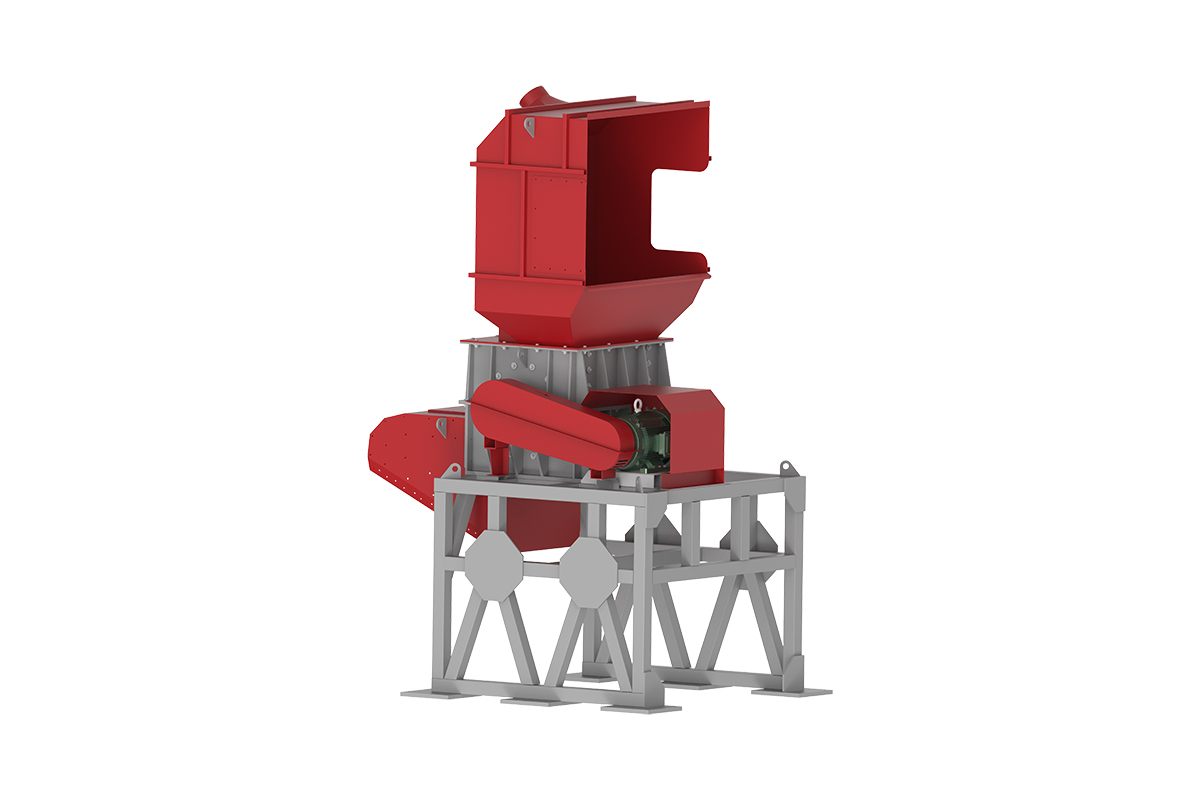

Hammer Mill Crusher

Contact Us

E-mail:sales@dgsaiko.com

tel:+86-137 2820 8855

Address: No.7, Industrial North Road 3, Chikan Village, Shipai Town, Dongguan City, Guangdong Province, China

Hammer Crusher

- Product Details

- Basic Parameters

Product Description of Hammer Mill Disintegrator

Core Purpose of the Equipment

The hammer mill disintegrator is a key supporting equipment at the rear end of a shredder. Its core function is to efficiently disintegrate materials that have undergone secondary crushing. It is particularly suitable for the subsequent processing of light slag from paper mills (mainly composed of plastic) and other materials. It can disperse agglomerated and caked crushed materials into more uniform granular forms, providing high-quality raw materials for subsequent sorting, recycling, or reprocessing processes.

Core Materials and Structural Advantages

Cabinet Design

Material Selection: The main body of the cabinet is made of NM400 wear-resistant steel plate. This material has excellent wear resistance, can withstand material impact and friction for a long time, and significantly extends the service life of the equipment.

Structural Technology: It adopts a mortise and tenon structure with densely distributed reinforcing ribs. This not only improves the overall strength and structural stability of the cabinet, avoids deformation during long-term operation, but also ensures the assembly accuracy of the equipment, reducing operating noise and failure risks caused by structural looseness.

Transmission and Operating Components

Main Shaft: Forged from high-strength steel, it has both high rigidity and fatigue resistance. It can stably transmit power under high-speed operation, withstand the instantaneous load caused by material impact, and is not prone to bending or breaking.

Blades: Also made of high-strength steel and processed through special heat treatment, they have high toughness and impact resistance. They can not only effectively disintegrate materials but also reduce blade chipping and wear caused by impurities in materials (such as a small amount of metal chips), lowering the replacement frequency of vulnerable parts.

Core Features of the Equipment

Low Wear and Tear: The cabinet, main shaft, and blades are all made of high-wear-resistant and high-strength materials. The key components have strong wear resistance, which reduces the replacement cost of daily vulnerable parts and lowers the equipment operation and maintenance investment.

Easy Maintenance: The equipment structure is designed to balance practicality and maintainability. The disassembly and assembly process of key components is simplified. Daily inspection, maintenance, and replacement of vulnerable parts do not require complex tools, shortening the downtime for maintenance and improving the overall operating efficiency of the equipment.

Strong Adaptability: Specifically designed for the rear-end process of shredders, it can accurately match the characteristics of materials such as light slag from paper mills (mainly plastic) after secondary crushing. It achieves uniform disintegration effect and can meet the raw material requirements of different subsequent processing (such as plastic recycling and granulation, material sorting).

| Model | Power(kw) | Diameter(Ф) | Speed(r/min) | Blade | Weight(kg) |

| 700 | 37kw | Ф640mm | 1000r/min | 20 | 3000kg |

| 1200 | 55kw | Ф960mm | 930r/min | 28 | 6000kg |

| 1500 | 75kw | Ф960mm | 930r/min | 36 | 7100kg |

English

English