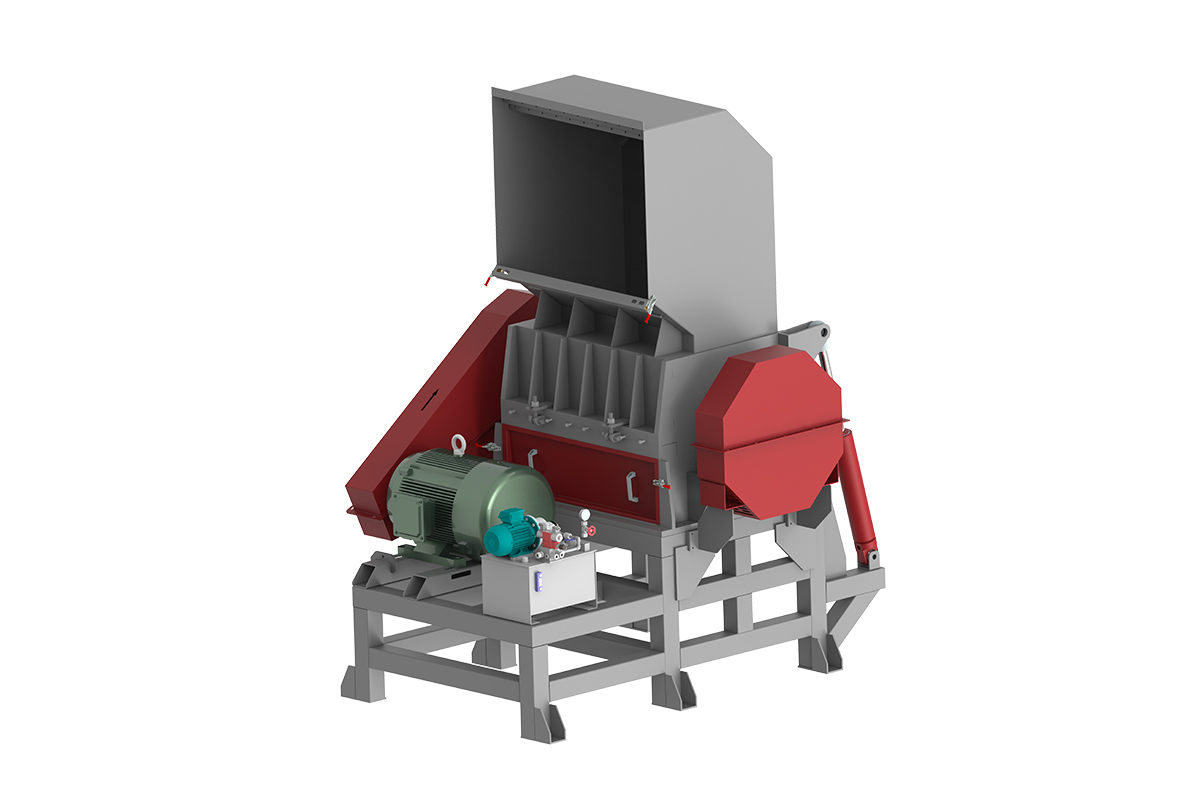

Soft PE PP Crusher

Contact Us

E-mail:sales@dgsaiko.com

tel:+86-137 2820 8855

Address: No.7, Industrial North Road 3, Chikan Village, Shipai Town, Dongguan City, Guangdong Province, China

Plastic Crusher

- Product Details

- Basic Parameters

- Technical Parameters

- FAQ

Plastic Crusher: Principle, Applicable Scenarios and Core Advantages

As a key equipment in plastic recycling and processing, plastic crushers are widely used in various plastic solid waste treatment scenarios due to their efficient crushing capabilities. Their core functions and characteristics can be explained in detail from the following dimensions:

Core working principle: high-speed cutting to achieve material crushing

The crushing function of the plastic crusher mainly relies on the "high-speed knife cutting" mechanism. The specific process is as follows:

Material Feed: Plastic materials to be crushed (such as lumps, flakes, and waste products) enter the crushing chamber through the feed port.

High-Speed Cutting: The main shaft within the crushing chamber drives multiple sets of cutting tools to rotate at high speeds (typically reaching hundreds to thousands of revolutions per minute). The cutting tools and fixed blades within the chamber create a shearing and impacting action, forcibly cutting and tearing large pieces of plastic.

Screening and Discharge: Crushed plastic particles are screened through a screen at the bottom of the chamber. Particles that meet the required particle size are discharged through the screen holes, while coarse particles that do not meet the standard remain in the chamber and continue to be crushed until the particle size meets the standard.

This principle ensures that the crushing process is efficient and uniform, and the output particle size can be adjusted according to needs by replacing screens with different apertures.

Applicable material range: covering all kinds of plastic materials

Its characteristic of being suitable for crushing all kinds of plastic materials specifically covers the following common plastic types, meeting the processing needs of materials in different forms:

General-purpose plastics: polyethylene (PE, such as plastic bottles and films), polypropylene (PP, such as plastic baskets and turnover boxes), polyvinyl chloride (PVC, such as pipes and profiles), polystyrene (PS, such as foam and plastic toys), etc.

Engineering plastics: ABS (such as home appliance housings and automotive parts), PC (such as CDs and lampshades), nylon (PA, such as gears and bearings), and other high-strength plastics.

Specialty materials: In addition to conventional block and sheet plastics, we can also process plastic film, plastic filament, waste plastic parts, injection molding scraps, and plastic packaging waste.

Industry application value: matching the solid waste recycling needs in multiple fields

Plastics Manufacturing Industry: Processes scraps (such as shavings, waste film, and substandard products) generated during the injection molding, extrusion, and blow molding processes. After crushing, these scraps can be directly reused in production, reducing raw material costs and achieving "scrap recycling."

Waste Plastics Recycling Industry: Serving as the "front-end crushing equipment" in the recycling industry chain, it crushes recycled waste plastics (such as used plastic bottles, used plastic barrels, and used plastic parts from household appliances) into uniform particles, providing qualified raw materials for subsequent cleaning and pelletizing processes.

Packaging Industry: Processes discarded plastic packaging materials (such as express delivery plastic bags, food packaging film, and plastic pallets), reducing the volume of packaging solid waste and facilitating transportation and subsequent recycling.

Automotive/Appliance Disassembly Industry: Crushes plastic parts (such as car bumpers and appliance housings) generated after disassembly, separating plastic from other materials such as metal, thereby increasing the purity of recycled plastics.

Agriculture: Processes agricultural plastic waste, including waste agricultural film (such as greenhouse film and ground film) and plastic seedling trays, to help reduce agricultural solid waste and recycle it.

Core advantages of the equipment: key features that adapt to industry needs

Efficient Crushing: The high-speed cutter design combined with a rational crushing chamber structure enables rapid processing of large quantities of plastic materials. Output per unit ranges from several hundred kilograms to tens of tons, meeting the needs of businesses of all sizes.

Adaptability: By changing the cutter type (e.g., claw, flat, or serrated) and the screen aperture, the crusher can adapt to plastic materials of varying hardness and shape, flexibly adjusting the output particle size.

Stable and Durable: The cutters are primarily made of high-strength alloy steel (e.g., SKD11 and Cr12MoV), offering wear and impact resistance for a long service life. The machine body is primarily constructed of welded steel plates, providing a stable structure and reducing operational vibration.

Safety and Convenience: Most machines are equipped with safety features such as overload protection, feed protection, and an emergency stop button to reduce operational risks. Some models feature convenient access to the cover for easy tool replacement and maintenance.

In summary, the plastic crusher achieves efficient crushing of various plastic materials through mature high-speed cutting principles. Its wide applicability and stable performance make it an indispensable core equipment in the recycling and treatment of plastic solid waste in various industries, providing key technical support for the development of the plastic circular economy.

| Model\Specifications | Motor power(kw) | Hydraulic station power(kw) | Rotation diameter(Ф) | Spindle speed(r/min) | Screen aperture(mm) | Machine weight(kg) |

| 800 | 45kw | 0.75kw | Ф570mm | 530r/min | Customizable | 2020kg |

| 1000A | 55kw | 1.5kw | Ф620mm | 556r/min | Customizable | 3250kg |

| 1000B | 55-75kw | 1.5kw | Ф680mm | 556r/min | Customizable | 3850kg-3950kg |

| 1200A | 75kw | 1.5kw | Ф660mm | 556r/min | Customizable | 4800kg |

| 1200B | 90-112kw | 1.5kw | Ф800mm | 556r/min | Customizable | 5050kg-5320kg |

| 1600 | 162kw | 3kw | Ф800mm | 500r/min | Customizable | 6500kg |

● Materials: Both the housing and blade holder are made of 45-gauge steel for high strength and resistance to deformation.

● Sturdy mortise and tenon welded steel structure.

● Manganese steel screen for wear resistance.

● Heavy-duty pulleys.

● Hydraulic flap for easy access and maintenance.

● Different blade roller configurations maximize productivity and service life.

● Drum types: Splayed blade roller, Slotted blade roller, Hanako blade roller, etc.

Q: What is a Plastic Crusher?

A: It shreds plastic waste into smaller pieces for recycling or disposal.

Q: Why use a Plastic Crusher?

A: It reduces volume, saves storage/transport costs, and prepares material for reuse.

Q: Where are they commonly used?

A: In recycling plants, manufacturing, and the waste management industry.

Q: How to choose the right crusher?

A: Consider plastic type, required output size, and capacity needs.

Q: Are there different types?

A: Yes, including single-shaft, double-shaft, and granulators for specific tasks.

English

English